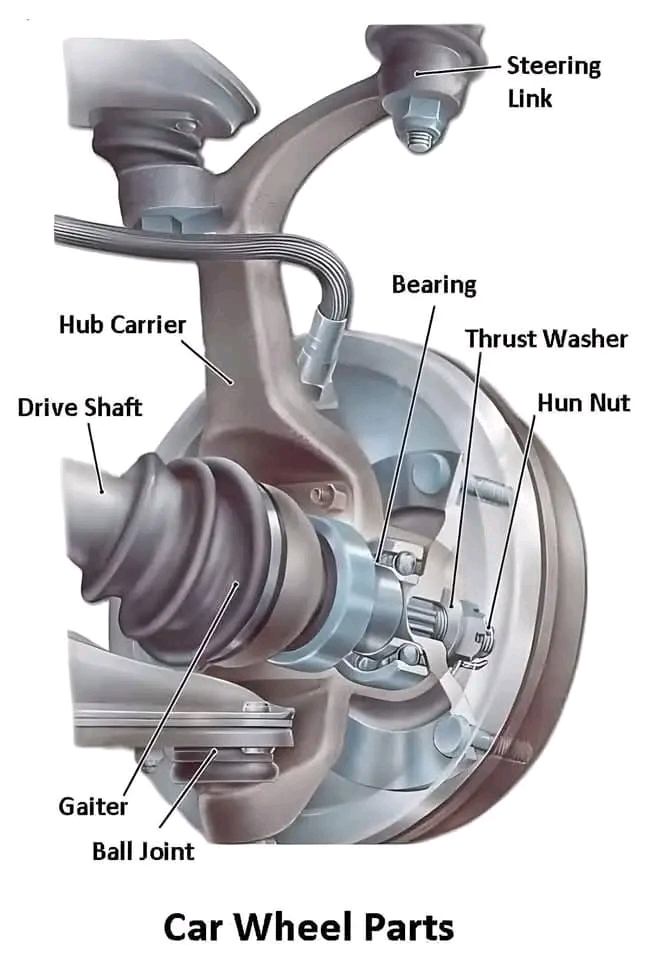

When you think about car wheels, you might picture just a simple, round object helping your car move. However, a car wheel is far more intricate than it appears. It comprises several key components, each with a unique role in ensuring a smooth and safe driving experience. Below is a comprehensive breakdown of car wheel parts and their functions:

- Rim: The Wheel’s Foundation

The rim forms the outer metal structure of the wheel, providing the essential base for the tire. It’s responsible for giving the wheel its shape and withstanding the pressures of driving.

Materials Used: Rims are often made from steel or alloy materials, chosen for their strength and durability.

Functionality: The rim supports the tire and ensures its secure attachment.

- Tire: The Rubber Grip on the Road

Encasing the rim, the tire is the rubber component that directly interacts with the road. It provides grip and absorbs shocks from uneven surfaces.

Tread Design: Treads on the tire surface improve traction and are tailored to different weather or terrain conditions.

Importance of Inflation: Proper tire pressure ensures optimal performance and safety while extending the tire’s lifespan.

- Hub: The Central Connector

The hub is the middle part of the wheel that connects to the car’s axle, making it pivotal for wheel rotation.

Bearing Housing: The hub houses bearings that reduce friction and allow the wheel to spin effortlessly.

Durability: Hubs are designed to endure significant stress and wear over time.

- Bearings: Facilitating Smooth Rotation

Wheel bearings are small, yet vital components that minimize friction between the wheel and axle, ensuring seamless rotation.

Sealed and Lubricated: Bearings are typically enclosed to protect against debris and moisture.

Signs of Wear: Noisy or wobbly wheels can indicate damaged bearings.

- Brake Disc: Critical for Stopping

Attached to the wheel hub, the brake disc (or rotor) works with the braking system to slow down or stop the car.

Friction Surface: When brake pads press against it, the resulting friction halts wheel movement.

Common Issues: Warped discs can reduce braking efficiency and need timely replacement.

- Brake Pads: Applying the Pressure

Brake pads are friction materials that clamp onto the brake disc, allowing the car to stop smoothly.

Wear and Tear: Over time, brake pads wear down and must be replaced for continued safety.

Different Materials: Pads are made from organic, metallic, or ceramic compounds.

- Brake Caliper: The Clamp Mechanism

The brake caliper houses the brake pads and uses hydraulic pressure to apply them against the brake disc.

Single vs. Dual-Piston Calipers: The type of caliper depends on the braking system’s requirements.

Maintenance Needs: Regular inspection ensures the calipers function properly.

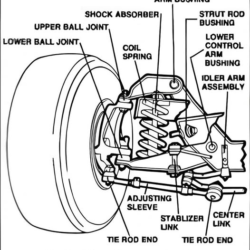

- Steering Knuckle: Connecting the Wheel to Steering

This metal component links the wheel hub to the suspension system and steering mechanism, enabling controlled wheel movement.

Pivot for Steering: The knuckle allows wheels to turn while supporting the vehicle’s weight.

Material Strength: Made from forged steel or aluminum for durability.

- Ball Joint: Allowing Smooth Articulation

A ball joint connects the steering knuckle to the suspension, offering flexibility for vertical and horizontal movement.

Role in Suspension: It absorbs shocks and helps the wheels adapt to uneven surfaces.

Signs of Wear: Clicking or loose steering may signal a failing ball joint.

- Tie Rod: Transmitting Steering Input

The tie rod connects the steering rack to the steering knuckle, transmitting driver inputs to the wheels.

Alignment Role: Tie rods help maintain proper wheel alignment, ensuring straight-line driving.

Durability: These parts must endure significant forces during turns and over bumps.

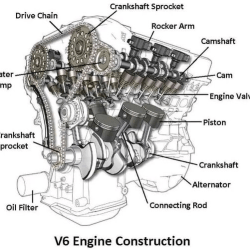

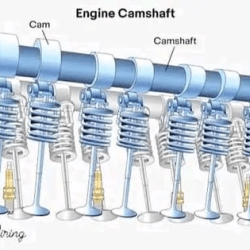

- CV Joint: Handling Power Transmission

The Constant Velocity (CV) joint allows the drive shaft to deliver power to the wheel at variable angles, crucial for front-wheel-drive cars.

Flexibility: CV joints adjust for up-and-down suspension movement and side-to-side steering.

Protective Boot: A rubber cover shields the joint from debris.

- Wheel Nuts: Securing the Assembly

Wheel nuts fasten the wheel to the hub, ensuring a secure connection.

Torque Requirements: Proper tightening prevents wheels from loosening while driving.

Materials: Made from strong metals like steel to resist wear and corrosion.

Each part of a car wheel works in harmony to provide stability, control, and safety. From the sturdy rim to the flexible CV joint, these components demonstrate the intricate engineering that goes into every vehicle.

By understanding these components, car owners can appreciate the complexity of their wheels and better maintain them for a smoother, safer ride.