China has completed its first million-tonne near-zero-carbon steel production line in Zhanjiang City, Guangdong Province, marking a major milestone in the country’s push toward green and low-carbon industrial transformation.

A Breakthrough for Green Steelmaking

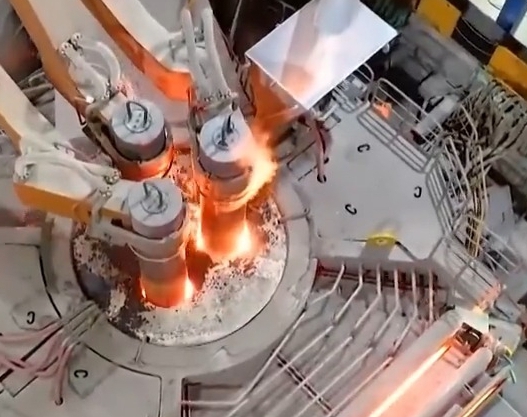

The newly completed production line represents a significant technological leap for China’s steel industry. It adopts an advanced hydrogen-based metallurgical electric smelting process, replacing traditional coke with hydrogen as the primary reducing agent.

This shift dramatically reduces carbon emissions and offers a viable path for the steel sector to lessen its long-standing dependence on fossil fuels—one of the biggest challenges facing heavy industry worldwide.

At the core of the process is a hydrogen-based shaft furnace, which produces direct reduced iron that meets targeted metallization rates. The system is further supported by high-efficiency green electric furnaces, significantly improving overall energy utilization.

Compared with conventional steelmaking processes, the new line can cut carbon emissions by 50 to 80 percent.

Massive Emissions Reductions

According to project staff at Baowu Steel’s Zhanjiang operation, the million-tonne near-zero-carbon steel line is expected to reduce carbon emissions by more than 3.14 million tonnes annually. This reduction is equivalent to the carbon absorption capacity of approximately 2,000 square kilometers of forest, underscoring the project’s environmental impact.

Aligned with National Green Development Goals

The achievement comes during China’s 14th Five-Year Plan period (2021–2025), which is widely regarded as a critical stage for the steel industry’s high-quality and sustainable development. Green transformation has been identified as a defining priority during this period.

From 2021 to 2024, China certified 126 new green steel plants, with the number increasing steadily each year. This reflects the industry’s accelerating transition toward cleaner production methods.

By the end of the third quarter of 2025, emissions of major air pollutants across the steel sector had dropped significantly:

- Sulfur dioxide: 0.18 kg (down 28%)

- Particulate matter: 0.22 kg (down 26.7%)

- Nitrogen oxides: 0.33 kg (down 36.5%)

These figures represent substantial improvements compared with levels recorded at the end of 2021.

Industry-Wide Energy Efficiency Gains

The China Iron and Steel Association has also promoted greener practices through its “extreme energy efficiency” initiative, launched during the 14th Five-Year Plan period.

In 2024 alone, the steel sector achieved energy savings equivalent to 10.5 million tonnes of standard coal, reducing carbon emissions by around 27.5 million tonnes. This reduction is comparable to the annual carbon sequestration of roughly 570 million mature trees.

A Model for the Future

The launch of China’s first million-tonne near-zero-carbon steel production line not only sets a new benchmark for the domestic steel industry but also provides a scalable model for global efforts to decarbonize heavy manufacturing. As hydrogen-based steelmaking technologies continue to mature, projects like this are expected to play a crucial role in shaping a more sustainable industrial future.