Onah Samuel Adakole

Abel John Ejila

In tecent times, they have been efforts to adopt additive

manufacturing in Nigeria, however, Benue state has not been

engaged most notably in the industrial adoption of this

technology. Additive Man5ufacturing is the new paradigm in

the manufacturing industry which is revolutionizing the

industrial landscape. This change looks at new engineering,

management, science, technology, and innovation skills to

fully harness the benefits offered by this advanced process of

technology for sustainable development. The current status of

industries in Benue State calls for an introduction of training

programs to equip engineers with contemporary skill sets in

additive manufacturing for improved design, production and

manufacturing, and management. Hence, additive

manufacturing technology should be adopted and exploited to

bridge the current gaps for the Engineers, Students and

Graduates to be relevant in the 21st century and positively

contribute to the inclusive socioeconomic development of the country.

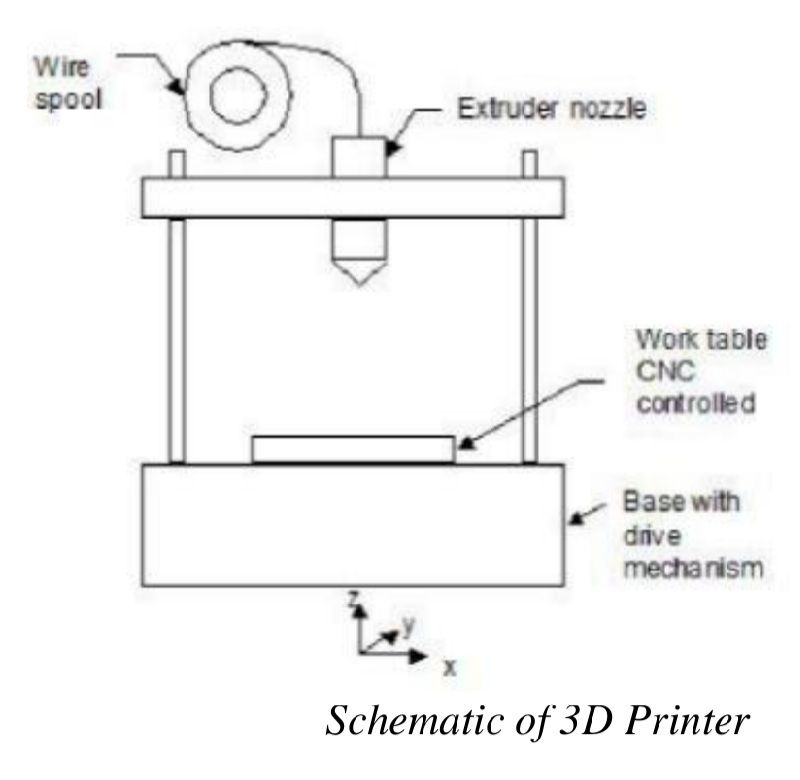

Additive manufacturing (AM), which is also known as 3-

Dimentional (3D) printing, is a manufacturing process that

produces objects in layer upon layer, by joining materials

from computer aided design (CAD). This virtual design

turns digital 3D models to solid objects [2, 3, 4].

AM technology is having an additive nature because it is considered an environmentally friendly process and and does not create waste unlike the other manufacturing methods which are subtractive in nature because they involve operations such as drilling, milling,

grinding etc. that remove materials from the work piece to

achieve their designed shape [5, 6]. As this new technique

evolves, it is projected to show a remarkable impact in the

manufacturing sector. AM brands the industry with recent

design flexibility and reduces the use of energy which helps to

shorten the time to market the desired product [7].

Following the new revolution in the manufacturing and

educational sector, global competition has been on the rise.

However, for any society to strive in this highly competitive

world, science, technology and innovation is a tool to maintain

and promote competitiveness for socio-economic growth.

According to Hernandez et l [1], engineering and technology

education must be valued by every nation in order to foster

competitiveness and industrial development amongst

developing nations and economic growth. To this effect,

engineering education policy should foster engineering and

engineering professional skills to promote industrial

development.

History of AM

AM is a disruptive technology that is becoming more prevalent

as the associated technology processes [10] and traces its roots

as far as the 19th century, particularly the fields of topography

and photo-sculpture, which lead the creation of solid 3D

structure by curing consecutive layers of photopolymer above

another [10, 11]. However, in 1981, with the creation of a

functional and fast prototyping system using photopolymers

by Hideo Kodama of Nagoya Municipal Industrial Research

Institute being published [12], this brought about more

activities where, in 1984, the stereo-lithography machine was

patented as well as several others by Charles Chuck Hull,

which became the core competencies of 3D systems [13]. Few years down the line, in 1988, Scott Crump had invented a 3D

printing technology called Fused Deposition Modelling

(FDM) [14]. Then in 1992, the world’s first stereolithographic

apparatus (SLA) machine was produced, while DTM

corporation, a company produced the world’s first selective

laser sintering (SLS) machine [15]. Nevertheless, between the

period of 1999 and 2010, implants and prosthetics were

manufactured via 3D printers, while spare parts of 3D printers

could now be produced by its own machines, and accessibility

of 3D printing being opened up to a larger part of society,

giving birth to 3D printers printing with different materials in

the same models to finished products [12]. It is a known fact

that new 3D Printer manufacturers explore their developments

using materials ranging from metals to porcelain, plastics

to sandstone, composite materials such as Kevlar and carbon

fibre and methods such as composite-based additive

manufacturing method (CBAM) and Continuous composite

3D printing [16, 17, 18]. Al-Makky and Mahmoud [19], 3D

printers have become the focus in manufacturing methods

after three decades. The early stages of additive

manufacturing are usually in a range of different terminologies from Layer manufacturing (LM) due to its nature of building up parts, to solid freeform manufacturing

because of its ability to fabricate complex shapes and objects.

The other name which is more common is Rapid prototyping

(RP); this was due to the fact that the products were not end

user products, but only prototypes.

The process evolved into AM based on the use of CAD to design and construct parts that are used directly for the purpose as finished products [20, 21].

Types of 3D Printing

3D printing can be grouped into few technological methods

namely:

i. Polymerization: Under Polymerization, two (2) types

of methods are involved, they are;

a). Stereolithography (SLA): this is the first original

industrial AM process. Its printers produce parts with

high detail level such as tight tolerance and smooth

surface finishing.

b). Digital Light Processing (DLP): this process

uses light to cure liquid resin. It is similar to the SLA

process, although the primary difference is SLA uses

UV laser while DLP uses digital light projector screen.

ii. Extrusion: The extrusion process only has one (1)

method which is;

Fused Deposition Modelling (FDM): this is also

known as a desktop 3D printing usually for plastic parts.

It is a fast method for producing physical models and

it’s very cost effective

iii. Powder Bed: The power bed methghas three (3)

methods which are:

a) Selective Laser Melting (SLM): this process

involves the use of a high-power density laser to melt

and fuse metallic powders together;

b) Selective Laser Sintering (SLS): this method is

used to reduce metal or a multi part in assemblies

into a single component; and

c) Electronic Beam Melting (EDM): this is a metal

3D printing technology that is controlled by

electromagnetic coils which helps to melt the metal

powder.

iv. Lamination: The lamination process has just one (1)

method which is;

Laminated object manufacturing (LOM): in the

process, the sheets which have been successfully

built by layering is bonded together with heat and

pressure, which is then cut with a carbon laser into

desired shapes [22].

Adoption of AM in Nigeria

With the speed at which the world is changing globally, most

developed countries have already applied AM in various

sectors such as architecture, healthcare, manufacturing,

construction, clothing, manufacturing and education. With this huge popularity the technology has gained, it is necessary for

developing countries and Africa at large to tap into this new

However, from the perspective of [23], additive manufacturing presents an enormous opportunity to improve the livelihood of

communities in developing countries by allowing the local

manufacturing firms both in the urban and rural areas to design

and produce innovative, robust and cost effective products that

can overcome the existing deficit in the manufacturing value

chain, which could lead to ease of life and income increase

Industry Adoption

Most companies that have adopted 3D priniting within the

country are maker’s labs and start-up hardware labs located

majorly at the western part of the country, the outfits regularly

provide training and third-party contracting for creating

solutions using AM. They include; 3D Place, Abuja,

CLINTONEL, Abia, Stalwart Technology Services, Lagos,

Stampar3D, Lagos, 3DMakery Africa, Lagos, ElePhab.Co,

Lagos, Freelove Concept, EdoTronic-Lab, Lagos, Gear Hub,

Kano, Microscale Abuja, Hub360, Lagos, and Xenopsis

Integrated Solutions, Benue.

Institutional Adoption

With over three decades of the introduction of additive

manufacturing globally, only a handful of Nigerian

universities and institutes are currently researching and using

the technology. They include: Prototype Engineering

Development Ilesa (PEDI), Edo University Iyamho (EUI) in

collaboration with Federal University of Petroleum

Resources, Effurun (FUPRE), Ahmadu Bello University

Zaria, Federal University Oye Ekiti, Afe Babalola

University Ado Ekiti (ABUAD), ELIZADE University Ilara

Mokin, General Electric National Agency for Science and

Engineering Infrastructure (NASENI), ElePhab, while Edo

University Iyamho (EUI) in collaboration with Federal

University of Petroleum Resources (FUPRE) and Afe

Babalola University (ABUAD) carried out a research,

design and development of a 3D printer from locally sourced

materials [26].

Role of Education in AM Advancement

With AM, people can be able to build whatever they imagine.

This can be achieved if the general public is educated about

AM. Notwithstanding, the dissemination of this technology to many potential users can spur up innovation and domesticate

manufacturing. Additive manufacturing has proved to hold a great potential for promoting STEM education both in the

formal and informal settings for both students and adults [27].

While in developed countries, such as the US, Australia,

United Arab Emirates, AM has presented great opportunities

to revamp the manufacturing programs in engineering

education at universities with new curriculums in advanced

product development. With the recent initiative in the US,

additive manufacturing is introduced at the secondary

education level (Defense Advanced Research Project

Agency) which is a manufacturing experimentation and

outreach (MENTOR) programme which provides 3D

printers to about 1,000 high school with the objective to

develop and motivate the next generation systems [28]

According to [27], a formal additive manufacturing education

has already been integrated into the curricula at different

levels in developed countries where educational materials on

rapid prototyping and manufacturing textbooks such as stepby-step manufacturing processes as well as engineering

materials have long been embedded as part of manufacturing

engineering courses at many engineering colleges and

technical schools.

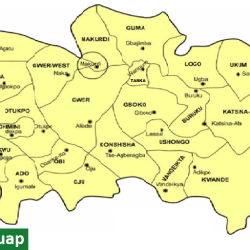

Adoption of AM in Benue

The adoption of AM in Benue is slow in both institutional and

industrial applications. So far, Only two 3D Printers are

surveyed to be in the state. These Printers are located at:

1. Calvary arrows college, Gboko (Since 2018).

Printer Model: Prusa i3 MK3S+

2. Xenopsis Integrated Solutions, Makurdi (Since

2019). Printer Model: Artillery Sidewinder X1

Activities of Xenopsis Integrated Solutions on AM

Xenopsis has continuously fast tracked the development of

embedded systems and additive manufacturing (3D printing)

within Nigeria through the rich team of indigenous researchers

and developers, promoting contemporary technological and

engineering ideas through knowledge sharing and technical

training for enthusiast and professionals. Xenopsis has also

been executing state of the art installation for building

electrification, home automation, solar system, CCTV and

embedded system design for security, system monitoring and

optimization.S

During the outbreak of COVID19 in 2020, xenopsis developed

solutions to curb the spread of the virus. This products were

rapid prototypes of structural members of a disinfection

chambers, hydraulic system accessories, and electronic

components and parts cases.

The Indigenous disinfection chamber launched at Jos Nigeria,

one of the hotspots of the pandemic was fitted with camera,

hand sanitizer dispenser, LCD Screen, Human Sensors and

Temperature Sensor. To provide a factory finish durability, the

fittings for the items listed above were precisely 3d printed.

Benefits of AM in Localized Industries

Manufacturing plays an essential role in a lot of industries. As

technology continues to improve, new methods of

manufacturing continue to emerge and 3d printing brings its

unique advantages. 3D printing applications are expanding in

various arrays of the industry, such as energy, aerospace,

automotive, biomedical, consumer goods, foot wears,

education, architecture, orthopedics, tissue engineering etc.

These benefits however, from progression are expected to

expand, and as time goes on, other areas of application will

spring up. 3D printing doesn’t essentially make sense for all

businesses, one must be able to analyze the drawbacks of cost

and speed to fit 3D printing into business. Tabletop machines,

which print primarily in plastics, have dropped in price in

recent years. They cost a few hundred dollars to several

thousand. Some notable desktop brands are Makerbot,

Deezmaker and Cubify. This provides an advantage to

improve businesses

1. Fabrication: Technical businesses such as repair shops,

can make models of hard-to-get-one-off parts and fix

machines that would have stayed broken because of no off

shelf spare parts.

2. Health: Treatments in the biomedical can be improved by

making 3D printing components for people that better

match their characteristics than the off-the-shelf

components. An instance is that It can replace the

conventional PVC Cast and provide a personalized light

weight wearable cast. 3D printing is however being

adopted to design and create custom prosthetic limbs

which will meet exact requirements of the patient. By

scanning the body of the patient as well as current bone

structure, designers and engineers are capable of recreating the lost portion of the such limb.

3. Fashion: Instead of 3D printing full items of clothing, 3D

printers in fashion are used to supplement parts of a whole

design, like embellishments, accessories, and buttons.

Small end-use accessories can be easily assembled in just

minutes or hours using 3D printing. 3D printing materials

with a flexible nature, can be used to add accent pieces or

unique embellishments onto the garment themselves. 3D

printing can also be used to create costume jewelry with

complex geometric shapes.

4. Arts and Crafts: AM is a game changer in the arts and

crafts, it takes the lid off what’s possible, giving creators

a wider imaginative scope and make-ability, providing a

really good bridge between technology and hands-on

crafting. Already, desktop 3D printers can make doodads,

such as plastic rings, figurines, and small gears and parts.

5. Food: Despite being a late-comer to the 3D printing party,

food is one evolving application that is getting people

thrilled and has the possibility of taking the technology

into the mainstream. In any case, food is essential for

human existence. 3D printing is emerging as a

contemporary method by which food is prepared and

presented.

6. Education and Research: Open-source 3D printers in

particular, are the latest technology making inroads into

the classroom. 3D printing allows students to create

prototypes of items without the use of expensive tooling

required in subtractive methods. Students design and

produce actual models they can hold. The classroom

environment allows students to learn and employ new

applications for 3D printing. RepRap, for example, has

already been used for an educational mobile robotics

platform.

7. Construction and home development: The use of 3D

printing to produce scale models within architecture and

construction has steadily increased in popularity as the

cost of 3D printers has reduced. This has enabled faster

turnaround of such scale models and allowed a steady

increase in the speed of production and the complexity of

the objects being produced.

Construction 3D printing, the application of 3D printing

to fabricate construction components or entire buildings

has been in development since the mid-1990s,

development of new technologies has steadily gained pace

since 2012 and the sub-sector of 3D printing is beginning

to mature.

8. Logistics and Supply Chain: With 3DP, the possibility

of mass customization will reduce inventory levels since

goods can be made to order. Thus, many steps in the

traditional supply chain can potentially be eliminated,

including distribution, warehousing, and retail. This will

go a long way in reducing the cost of goods to the final

consumers as significant percentage of cost of goods sold

usually goes to supply and distribution chain.

Conclusion:

The technology is said to be one of the most significant

industrial developments of this decade and is thus expected to

keep growing. This makes it an important element to be tapped

into by any developing society like Benue state and Nigeria at

large. The technology has a wide variety of application that

cuts across numerous sectors and fields. It is applied in

industrial designs, automotive design, consumer commodities,

biomedical engineering, and dentistry (dental); as well as

aerospace among several others. The technology presents a

great deal of opportunities Benue, a developing State, that still

grapples with the challenge of meeting needs of its citizens in

various sectors where application of the technology promises

vast solution to some inherent problems. Equipping Schools

with this technology and training young engineers with the

right skills will provide a competitive advantage for innovative

excellence and drive development.

References

[1] P. Hernandez, R. Bodin, J. W. Elliot, B. Ibrahim, K.

Rambo-Henandez, T. Chen and M. De Miranda, “Connecting

the STEM dots: Measuring the effect of an integrated design

intervention,” International Journal of Technology and Design

Education, vol. 24, no. 1, pp. 107-120, 2014.

[2] S. Chong, G. Pan, J. Chin and P. L. Show, “Integration of

3D Printing and Industry 4.0 into Engineering Teaching,”

MPDI Journal of Sustainability, 2018.

[3] T. A. I. C. F42, “Additive Manufacturing

Technologies,” http://www.astm.org/COMMITTE/F42.htm,

2017.

[4] K. Waseem, H. A. Kazmi and O. H. Qureshi, “Innovation

in Education – Inclusion of 3D-Printing Technology in Modern

Education System of Pakistan: Case from Pakistani

Educational Institutes, Vol.8, No.1,” Journal of Education and

Practice, vol. 8, no. 1, 2017.

[5] C. Beyer, “Strategic Implications of Current Trends in

Additive Manufacturing,” J. Manuf. Sci. Eng, vol. 136, no. 6,

p. 064701, 2014.

[6] S. Huang, P. Liu, A. Mokasdar and L. Hou, “Additive

manufacturing and its societal impact: a literature review,”

Int. J. Adv. Manuf. Technol, vol. 67, no. 5-8, pp. 1191-

1203, 2013.

[7] W. Report, “3D Printing and Additive Manufacturing

State of the Industry,” Annual Worldwide Progress Report,

Wohlers Associates, 2014.

[8] Y. Chien, “Developing a Pre-engineering Curriculum for

3D Printing Skills for High School Technology Education,”

EURASIA Journal of Mathematics Science and Technology

Education, vol. 13, no. 7, pp. 2941-2958, 2016.

[9] T. Kelley and N. Kellam, “A theoretical framework

to guide the re-engineering of technology education,”

Journal of Technology Education, vol. 20, no. 2, pp. 37-

49, 2009.

[10] D. Young, Polymer Additive Manufacturing Technical

Brief, [Online] available at www.uammi.org-new-08, 2018.

[11] E. Matias and B. and Rao, “3D Printing: On Its

Historical Evolution and the Implications for Business,” pp.

551-558, 2015.

[12] Autodesk “History of Additive Manufacturing, its older

than you are, (that is if you are under 30 30).,” [Online]

Available at: https://redshift.autodesk.com/history-of-3dprinting/, 2014.

[13] H. Lipson and M. Kurman, Fabricated: The new world of

3D printing, New York: NY: John Wiley and Sons., 2013.

[14] I. Gibson, D. W. Rosen and B. Stucker, Design for

Additive Manufacturing. Additive Manufacturing

Technologies: Rapid Prototyping to Direct Digital

Manufacturing, Springer US, 2010.

[15] J. Kollataj, “Additive Manufacturing (3D Printing): A

Potential Future for Tennis rachet production, “Degree

thesis, Degree Program Plastics Technology, 2016.

[16] C. Composites, “Continuous Composites,” [Online]

Available at: http://continuouscomposites.com/, 2016.

[17] Markforged, “High Strength 3D Printing with

Continuous Carbon Fibre,” [Online] Available at:

https://markforged.com/, 2016. Seigha Gumus et al.

APWEN 2020 National Conference 82

[18] I. Shapeways, “3D Printing Materials Comparison

Sheet,” [Online] Available at:

https://www.shapeways.com/materials/material-options ,

2016.

[19] M. Al-Makky and D. Mahmoud, “The Importance of

Additive Manufacturing Processes in Industrial

Applications,” in Proceedings of the 17th Int. AMME

Conference,, 2016.

[20] E. N. Hopkinson and P. M. Dickens, Rapid

Manufacturing, John Wiley & Sons, 2016.

[21] Y. Zhai, D. A. Lados and J. L. LaGoy, “Additive

Manufacturing: Making Imagination the Major Limitation,”

Jom, vol. 66, no. 5, pp. 1-9, 2014.

[22] O. Spencer, O. Yusuf and T. Tofade, “Additive

Manufacturing Technology Development: A Trajectory

Towards Industrial Revolution,” American Journal of

Mechanical and Industrial Engineering, vol. 3, no. 5, pp. 80-

90, 2018.

[23] F. R. Ishengoma and A. B. Mtaho, “3D Printing:

Developing Countries Perspectives,” International Journal of

Computer Applications, vol. 104, no. 11, pp. (0975-8887),

2014.

[24] R. Beyers, A. Blignaut and L. Mophuti, “Mobile

FABLABS: Local and Rural Innovation in South Africa,”

in Proceedings of World Conference on Educational

Multimedia, Hypermedia and Telecommunication, 2012.

[25] G. Aleksandra. “ 3D Printing, Shaping Africa’s Future”

Issue brief April, 2018.

[26] V. A. Balogun, O. B. Otanocha and A. O. Ibhadode,

“The Impact of 3D Printing Technology to the Nigerian

Manufacturing GDP,” Modern Mechanical Engineering, vol.

8, pp. 140-157, 2018.

[27] S. Kalpakjian and S. R. Schmid, “Manufacturing

Processes for Engineering Materials,” in 5th Ed., Prentice

Hall, , Upper Saddle River, NJ, 2008.

[28] Y. Huang and M. Leu, “Frontiers of Additive

Manufacturing Research and Education,” Report of NSF

Additive Manufacturing Workshop., 2014.

Source: Accelerating Additive Manufacturing in Benue State

A presentation at the Nigeria Society of EngineersMakurdi Branch April 2021 Technical Meeting

Onah Samuel Adakole1

Abel John Ejila2