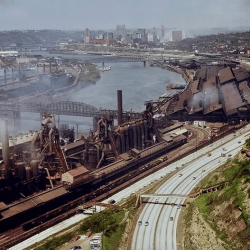

Foundry and Pattern Making Shop is a facility of Engineering Works Complex of Ajaokuta Steel Company

Foundry shop is designed to produce about 7,000 Metric Tons of casting per annum, including 3,550 MTonns of cast iron, 3260 MTonns of steel and 190 Metric Tons of Non-Ferrous metal castings.

• The shop is equipped with a spectrometer Laboratory for determining the chemical composition of Ferrous materials.

• The Pattern Making shop is designed to manufacture pattern for the foundry. It can produce up to 460 cubic meters of wooden items.

• Some of the casting done on a regular basis for external customers are jaw crusher, Grinding media of various sizes, roller shells, Gears, Pulley, Flywheel, Non-Ferrous bushes etc.

The core equipment of the shop is as specified below:

• Two Electric Arc Furnaces 6,000 kg capacity, each.

• One Induction Mixer Furnace of 10,000 Kg capacity.

• One Induction Melting Furnace of 1000kg capacity.

• One Fuel Fired crucible Furnace of 100Kg capacity.