The Dagombas, Gonjas, Mamprussis and Moshies, all off whom occupy the northern part of modern Ghana, were prominent northern tribes to establish powerful kingdoms some hundreds of years before the establishment of similar powerful kingdoms in the south by their Akan counterparts.

This they were able to achieve because they possessed skilful craftsmanship in the art of iron smelting that enable them to manufacture weapons for defence and security, besides use of iron in manufacturing implements used in day to day activities.

The iron smelting workers would carefully pick up stones that contained large amount of iron technically called iron ores. They usually prefer ores of the size of small pebbles to hasten the process of smelting. If they are of bigger size they would break them into smaller pieces. Cylindrically shaped holes of height about 1 – 3 feet and diameter about 3 feet would then be dug into the ground.

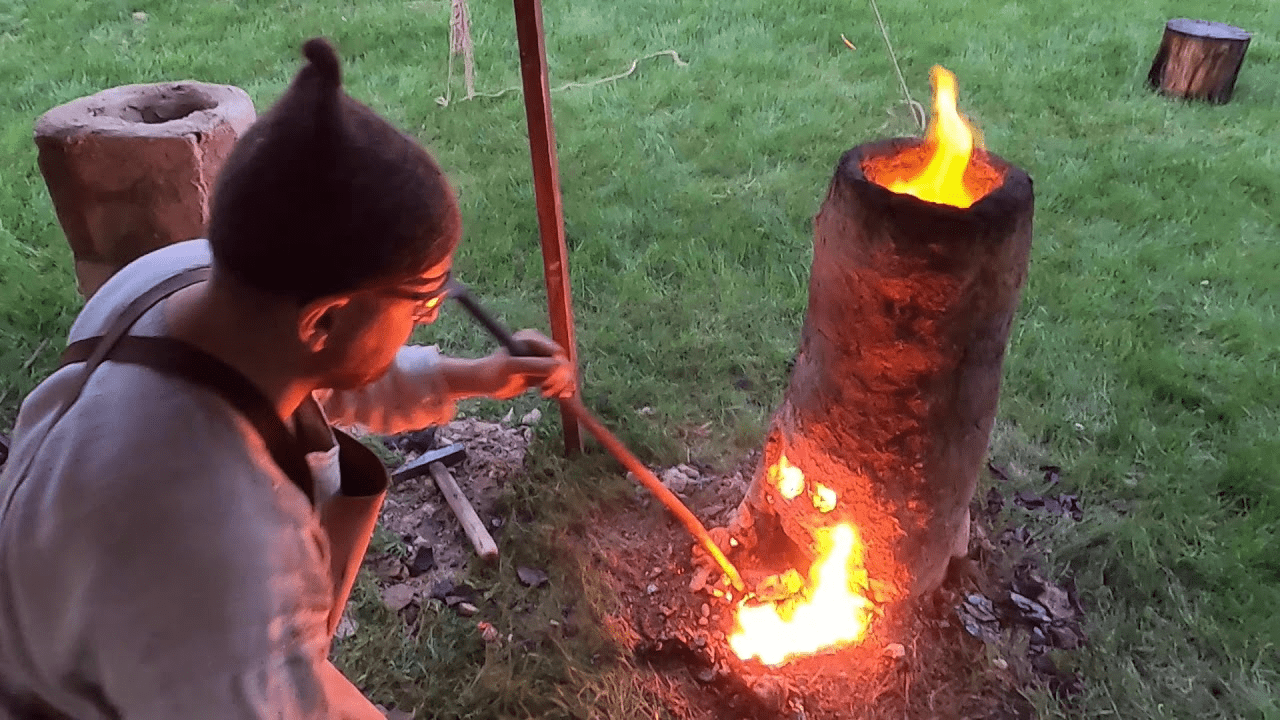

It would then be filled with the iron ores on top of which would be placed dry roots of trees. On top of the dry woods would then be placed some additional ores. (See Fig). A pair of bellows, constructed from clay and specially made leather from animal hides, would then be connected to the hearth through a pair of clay pipes and some clay device.

These two pipes would then join into a common clay tube or pipe near the center of the fire wood (See Fig 2). Thus as the skin leathers are raised up and down air is allowed into the bellows and forced into the center of the fire, which would be initially lit using some embers.

As more rapidly blown into the fire the Temperature of the latter would increase turning the wood into charcoal to produce carbon dioxide and carbon monoxide inside the hearth.

These would then react with the iron ores to produce the iron, which due to the high temperatures inside the hearth would melt the iron.

The melting of the iron signifying the success of the process would be marked by the emanation of some SSS sounds. After that the red hot and molten iron, would flow through an outlet in the form of a gutter cut from the cylindrical hole dug in the ground. See the attached figure. After cooling for a day solidified iron would then be removed the following day and cut into pieces.

These pieces would then be sold to the blacksmith who would use them to manufacture various implements like the hammer, anvil and weapons like the arrow, spear, sword, cutlass, knives etc.

Modern process of iron smeltering is only an improved version of the traditional description. Thus instead of using charcoal to produce gassed to reduce the iron, a combination of coke and limestone are used. These give greater amount of the gases besides silica materials present in reacting with silica and other impurities in ore to form slag.

The combination of chemical impurities with the molten iron leads to the formation of pig or wrought iron in both the traditional and modern smelting techniques. I have described the traditional process as an art at some point. Not only the African smelting process, but all other smelting processes used by other civilizations before modern times are so described.

This should be so because criteria for judging as to the crucial point at which some special reaction might have occurred is always based on the human senses. For examples, in above description, the point at which the actual extraction of the iron took place was detected by the emanation of some sss or hissing sound. So here are using the human cars to detect that point.

Similarly, in the same process as used in some civilizations, they would detect that point by the particular colour the molten iron may emit at the point. Here as well as judgment or detection was used on sight. But as you will agree with me, the detection ability of individuals using the organs of eyes, cars and other sensory organs are different.

Secondly, when faculty it implies that crucial point would be missing. To overcome these problems modern science invented the thermometer which uses such metallic liquids as mercury to detect the melting point of iron. Here there is only one temperature value and nothing else. For this exactitude, precision and accuracy in determining this crucial point in the process we say that modern smelting of iron is scientific.

GUNPOWDER

In the same vein, they could manufacture some crude form of gunpowder described as follows: First a portion of ground would be selected where people would be selected where people would be encouraged to urinate. After urinating there for some reasonable length of time, the soil from the spot would be collected and put into some kind of sieve made by punching the soil containing the urine into the sieve, the latter would be lined with leaves. The sieve containing the soil would then be put on top of another metallic container. Small quantities of water would then be sprinkled on the soil daily, whilst drippings from the sieve would be collected into the second metallic container.

CRYSTALS

Having collected the drippings over a long period of time, the container would then be boiled till the solution become syrup thick. It is left over-night for crystals to form, which would then be picked with the hand and ground into extremely fine powder using grinding stones.

After that the powder obtained from the urine crystal and the charcoal powder would be mixed intricately to form gunpowder. The following is the scientific explanation of the above described process: Urine contains urea which, through biotic processes, becomes uric acid when urinated into soil.

The uric acid then reacts with metallic iron in the soil to form salts of urea called ureates. When dried and ground into fine powder and mixed with the charcoal, the ureate would form the oxidizer and the charcoal the fuel. When fire is ignited by heat or fire it will explode as gunpowder.

Before the advent of European Powers in the then Gold Coast the North was smelting iron from iron ores for use in the manufacture of everyday appliances and weapons. The skill then spread to the South. Last but not the least the large-scale introduction of modern iron and steel by European Powers naturally killed the African innovation and imitative, since they proved to be better and cheaper.

But then the point is established for good that the African has been civilized and not primitive, as others want us to believe. Similarly, there are strong evidences to the effect that he could also manufacture some crude form of gunpowder.