A Box Girder Bridge is a type of bridge known for its hollow, box-shaped girder beams, which give it a unique blend of structural integrity and efficiency. Widely used in modern engineering for highways, railways, and river crossings, these bridges are designed to handle long spans, heavy loads, and challenging environmental conditions.

In this guide, we’ll explore the design principles, construction techniques, materials used, and the applications that make Box Girder Bridges a popular choice in civil engineering.

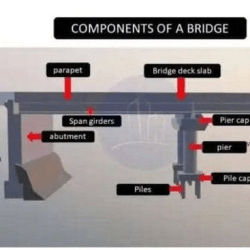

1. What is a Box Girder Bridge?

A Box Girder Bridge features a beam structure with a hollow, box-shaped girder that supports the deck. Typically, the cross-section of the box girder is rectangular or trapezoidal. These bridges are frequently constructed using prestressed concrete, structural steel, or a composite of steel and reinforced concrete.

- Prestressed Concrete: Adds compressive stress, reducing tensile stress and improving durability.

- Structural Steel: Known for strength and flexibility, making it ideal for high-stress conditions.

- Composite Materials: A combination of steel and reinforced concrete adds robustness and cost efficiency.

2. Key Characteristics of Box Girder Bridges

Box Girder Bridges have characteristics that differentiate them from other types:

- Hollow Box Shape: Minimizes material usage while maintaining strength.

- Torsional Resistance: Particularly suitable for spans that experience significant torsional or twisting forces.

- Long Spans: Suitable for wide spaces without the need for additional supports.

3. Types of Box Girder Bridges

Box Girder Bridges vary based on materials, construction techniques, and the specific engineering needs of each project:

- Single Box Girder: Typically used for shorter spans or lower load requirements.

- Multi-Box Girder: Used for wider spans, with multiple parallel box girders for added strength.

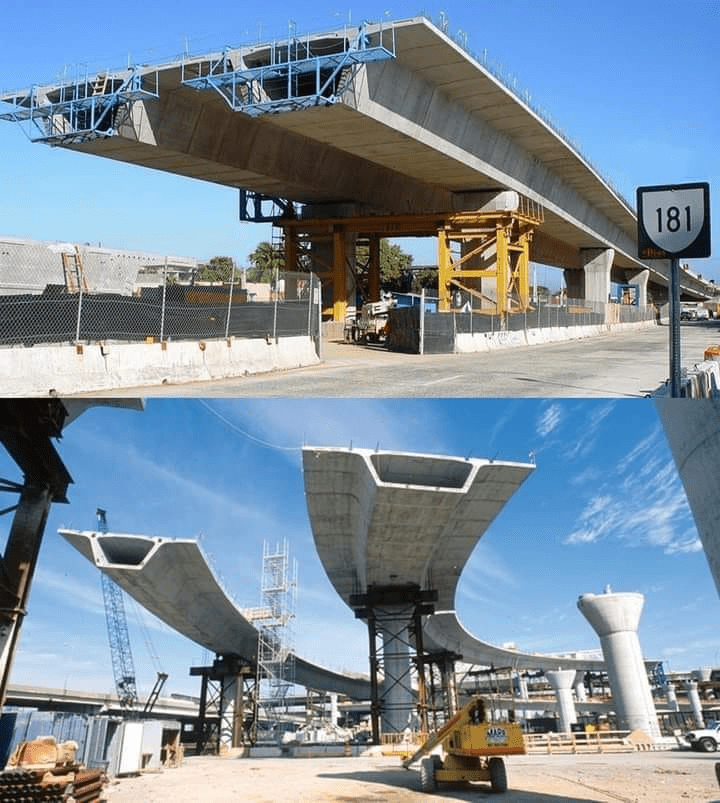

- Segmental Box Girder: Prefabricated sections are combined to create larger spans efficiently.

- Curved Box Girders: For roads and railways requiring turns, curved box girders offer improved alignment and support.

4. Design Principles of Box Girder Bridges

- Cross-Sectional Design: The box shape resists bending and twisting, allowing for long, unsupported spans.

- Load Distribution: Efficiently distributes loads across the entire cross-section.

- Material Selection: Depending on load demands, budget, and environmental factors, engineers may select concrete, steel, or composite materials.

5. Materials Used in Box Girder Bridges

- Concrete: Widely used for its durability and cost-effectiveness in box girder bridges.

- Steel: Known for tensile strength, often used in environments with high stress demands.

- Composite Materials: Blend the best properties of steel and concrete, offering both strength and flexibility.

6. Construction Techniques

A. In-situ Casting

In-situ casting involves creating the box girders on-site, which can be advantageous for large bridges where transportation of massive components is challenging.

B. Prefabrication

Prefabricating box girders in a factory setting ensures quality control and speeds up the construction process. These prefabricated segments are transported to the site and assembled with cranes or launching gantries.

7. Advantages of Box Girder Bridges

Box Girder Bridges offer several unique benefits:

- Strength and Stability: The box shape adds structural integrity and reduces material use.

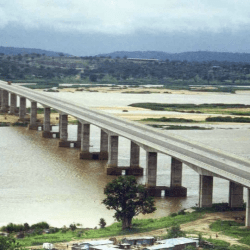

- Longer Spans: Ideal for projects requiring long, continuous spans.

- Aesthetic Appeal: Smooth and streamlined, box girders provide a modern look.

8. Challenges in Box Girder Bridge Construction

While beneficial, Box Girder Bridges come with certain challenges:

- Complex Design Requirements: Requires precision in engineering and assembly.

- Higher Initial Costs: Use of advanced materials and specialized labor can increase upfront costs.

- Maintenance Needs: Regular inspections are necessary due to stress and environmental impact.

9. Case Studies: Notable Box Girder Bridges

- Humber Bridge, UK: One of the longest single-span suspension bridges, known for its box girder construction.

- Oresund Bridge, Denmark-Sweden: This box girder bridge spans both sea and land, showcasing flexibility in design.

10. FAQs

Q1: What makes a box girder bridge different from other bridge types?

A box girder bridge uses a hollow box structure, providing greater torsional strength and the ability to handle long spans with fewer supports.

Q2: How are box girder bridges constructed?

They can be constructed by in-situ casting or by assembling prefabricated segments on-site with cranes or gantries.

Q3: What materials are commonly used in box girder bridges?

Box girder bridges are typically made from prestressed concrete, structural steel, or a composite of steel and reinforced concrete.

Q4: Why are box girder bridges used for curved roadways?

The hollow box design resists torsional forces, making them ideal for curves and slopes.

Q5: Are box girder bridges expensive to build?

They may have higher initial costs due to materials and specialized construction methods, but their durability and longevity can offset costs over time.

Q6: What are some examples of box girder bridges?

Notable examples include the Oresund Bridge in Europe and the Tokyo Bay Aqua-Line in Japan.