Pre-tensioning is a specialized technique employed in modern construction to enhance the strength, durability, and functionality of concrete structures, particularly roads and bridges. As a subset of prestressed concrete technology, pre-tensioning is vital for ensuring these structures can handle heavy loads and maintain long-term stability. Below is an overview of the pre-tensioning process, its benefits, challenges, and significance in infrastructure development.

The Pre-Tensioning Process: Key Steps

- Tensioning Steel Strands

- High-strength steel tendons or strands are stretched along a casting bed to a specific level of tension using hydraulic jacks.

- The strands are anchored securely at both ends to maintain tension throughout the process.

- Pouring Concrete

- With the tendons in tension, concrete is poured over and around them, completely encasing the steel strands.

- The tensioned tendons interact with the concrete during the setting process, ensuring a strong bond.

- Cutting the Tendons

- Once the concrete achieves the required strength, the steel tendons are cut.

- This action releases the tension, transferring compressive forces to the concrete, which strengthens it against tensile stresses.

How Pre-Tensioning Enhances Concrete Structures

Concrete is inherently strong in compression but weak in tension. Pre-tensioning addresses this limitation by:

- Imparting Compressive Stress: Counteracts tensile forces experienced during the structure’s lifecycle, reducing the likelihood of cracking.

- Improving Load Capacity: Allows the structure to bear heavier loads by balancing internal stresses.

- Enhancing Durability: Increases resistance to environmental stressors, ensuring longer service life.

Advantages of Pre-Tensioning

Pre-tensioning offers numerous benefits for infrastructure development:

- Improved Span Efficiency:

- Enables the construction of longer spans with fewer supports, making designs more economical.

- Reduces girder lines and increases girder spacing, streamlining bridge and road construction.

- Reduced Material Requirements:

- Shallower superstructures save material costs without compromising strength.

- High-strength concrete and steel strands minimize bulk.

- Durability and Crack Resistance:

- Compression from pre-tensioning controls cracking caused by tensile forces, extending the lifespan of structures.

- Enhanced Aesthetics and Functionality:

- Longer spans and fewer supports result in sleek, visually appealing designs.

Challenges in Pre-Tensioning

While the technique has transformative benefits, it also poses several challenges:

- Fabrication Complexity:

- Requires precise manufacturing of long and slender girders, often exceeding 100 feet in length.

- Handling and Transportation:

- Long girders are difficult to transport and prone to damage during shipping.

- Erection Difficulties:

- Specialized equipment and techniques are needed to erect pre-tensioned girders safely.

- Cost Implications:

- Initial costs are higher due to the need for high-strength materials and advanced machinery.

These challenges are mitigated through innovations in design optimization, modern construction technology, and collaboration between engineers and contractors.

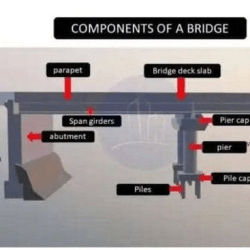

Applications of Pre-Tensioning

Pre-tensioning is widely used in:

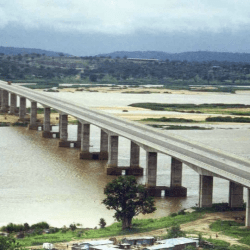

- Bridges:

- Enables longer spans with fewer piers, reducing obstructions in waterways or roadways beneath.

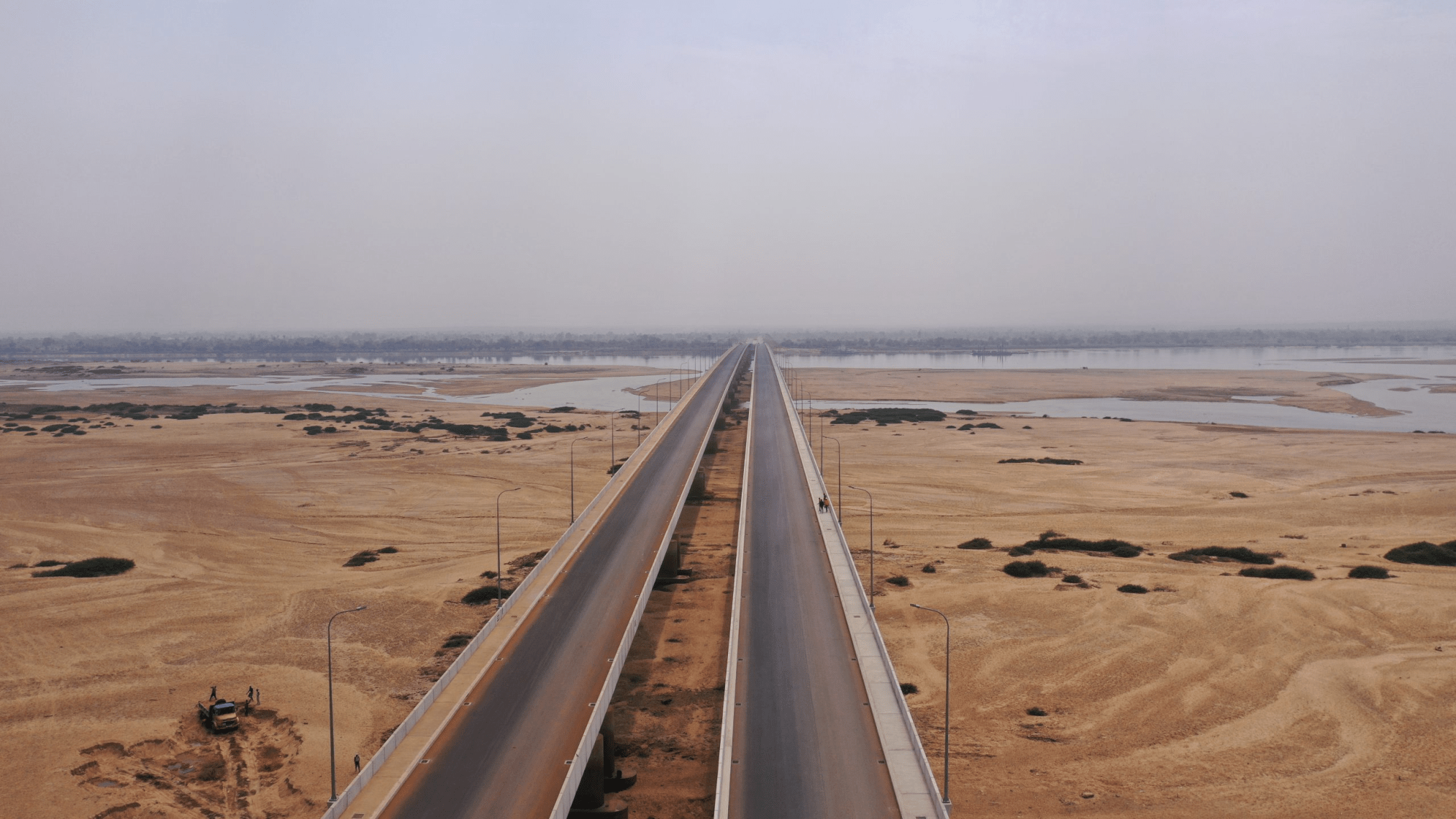

- Highway Construction:

- Provides robust and durable pavement that can withstand heavy traffic loads.

- Railway Infrastructure:

- Supports high-speed rail systems with resilient and crack-resistant tracks.

- Commercial and Residential Projects:

- Used in floor slabs, beams, and precast elements to improve structural efficiency.

Economic and Environmental Impact

Pre-tensioning contributes to sustainable and cost-effective construction:

- Resource Optimization: Fewer materials are required due to efficient load distribution.

- Longevity: Durability reduces maintenance and repair costs over time.

- Reduced Carbon Footprint: Longer service life translates to fewer reconstructions, lowering environmental impact.

Pre-Tensioning vs. Post-Tensioning

Pre-tensioning and post-tensioning are both prestressing methods but differ in execution:

| Feature | Pre-Tensioning | Post-Tensioning |

|---|---|---|

| Execution | Steel strands are tensioned before casting concrete. | Strands are tensioned after concrete sets. |

| Typical Application | Precast elements like girders and slabs. | Cast-in-place structures like bridges. |

| Equipment Needs | Casting beds and hydraulic jacks. | Ducts, anchors, and tensioning equipment. |

Pre-tensioning is an indispensable technique in modern construction, enabling engineers to build structures that are not only stronger and more durable but also more efficient and cost-effective. Its role in infrastructure—particularly in roads and bridges—underscores the advancements in materials science and engineering that continue to shape the built environment.

Through innovation and careful design, pre-tensioning bridges the gap between functionality and aesthetics, paving the way for a more resilient and sustainable future in construction.